Change Language :

drylin® T - Technical data

drylin® - Technical data

| glide bar | |

|---|---|

| Material | Aluminium, extruded section |

| Material | AlMgSi0.5 |

| coating | Hard-anodised aluminium, 50µm |

| Hardness | 500 HV |

| Sliding carriage | |

|---|---|

| Base structure | Aluminium, extruded section |

| Material | AlMgSi0.5 |

| coating | Anodised, E6/EV1 |

| Sliding elements | Maintenance-free plain bearing material iglidur® J |

| Bolts, springs | Stainless steel |

| Lid | plastic (TW-01/TWA-01), steel (TW-02) |

| Max. Surface Speed | 15 m/s |

| Temperature range | -40 °C to +90 °C |

drylin® T in use in the packaging industry

Special specification

- Due to low inertia and the absence of rolling components, high accelerations and - in the short term - extreme speeds of up to 30 m/s are possible

- drylin® T linear guideways run dry and are therefore insensitive to dirt. Dirt particles cannot become embedded in lubricants

- Particularly suitable for use in food, medical and clean room technology, as no lubricants are released into the environment

- The corrosion resistance allows the drylin® T linear guideways to be used under water

- Easy high-pressure cleaning

- Low vibration and very quiet

- The pairing of the sliding partners anodised aluminium and iglidur® J has a particularly low breakaway torque

- drylin® T can be combined and interchanged with standard linear ball bearing guides

- Please note that this is a technical surface. Depending on the coating thickness, optical colour variations cannot be avoided

drylin® T - permissible load capacity, static

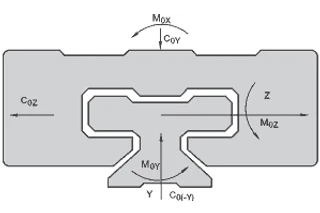

Diagram 01: Marking of the directions

| Type | C0Y [kN] | C0(-Y) [kN] | C0Z [kN] | M0X [Nm] | M0Y [Nm] | M0Z [Nm] |

|---|---|---|---|---|---|---|

| 04-07 | 0.2 | 0.2 | 0.1 | 1.2 | 0.6 | 0.6 |

| 04-09 | 0.48 | 0.48 | 0.24 | 3.4 | 1.8 | 1.8 |

| 04-12 | 0.96 | 0.96 | 0.48 | 9.2 | 4.4 | 4.4 |

| 04-15 | 1.4 | 1.4 | 0.7 | 17 | 8 | 8 |

| 01-15 | 4 | 4 | 2 | 32 | 25 | 25 |

| 01-20 | 7.4 | 7.4 | 3.7 | 85 | 45 | 45 |

| 01-25 | 10 | 10 | 5 | 125 | 65 | 65 |

| 01-30 | 14 | 14 | 7 | 200 | 100 | 100 |

drylin® T - permissible load capacity, dynamic

X = velocity v [m/s]

Y = load F [N]

A = y- direction

B = z-direction

diagram. 02: drylin® T - permissible load capacity, dynamic

Consulting

I look forward to answering your questions

igus® (Pty) Ltd. +27 11 312 1848Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr