Change Language :

Choosing the right twisterchain new

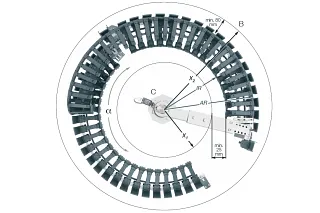

For machine elements that move in a circle both to the left and to the right, the rotation angle is calculated by adding the two angles.

Legend

B = Outer limit

C = Machine

D = Fixed end

E = Upper limit

AR = Outer radius chain

IR = Inner radius chain

R = Bend radius chain

X1 = Inner machine installation space

X2 = AR chain incl. clearance

T = Pitch

HF = Chain height incl. 50mm clearance

H = Chain height

K = Add-on for bend radius

hi = Inner height of the chain

ha = Outer height of the chain

α = Rotation angle

Instructions for designing the twisterchain new using an example:

If you would like us to do the project planning for you, please use the igus project planning system. If you would like to determine the energy chain and support trough yourself, please work through the following points and enter the results in the calculation aid at the end of the section.

1. Select series and determine chain width - customer data e.g:

- Available installation space outer radius = 592mm

- Available installation space inner radius = 311mm

- α rotation angle = 220°

- Clearance height = 466mm

- Max. Ø cable customer = 22mm (7.5xd)

Estimate the dimensions of the chain based on the interior separation with filling and select the series, or check the maximum cable diameter and select the series based on the next largest permissible Ø. (We recommend taking into account a cable clearance of approx. 20% of the inner height and width of the chain for the inner height).

Max. Ø cable diameter twisterchain: TC32 = 28mm | TC42 = 38mm | TC56 = 50mm Example: max. Ø cable diameter customer 22mm = TC32 series (next larger)

2. Select outer radius AR

Select the next smaller X2 of the chain from the available installation space of the outer radius. Subtract 80mm from dimension X2 to obtain the required outer radius AR. For selection of chain outer radii, see table dimension X2 of the corresponding series.

Formula AR = X2 - 80mm

Example:

1. Available installation space outer radius 592mm => 580mm (X2)

2. X2 580mm - 80mm => AR 500mm (next smaller selected)

3. Select inner radius IR

Add 25mm to the available installation space of the inner radius and then select the largest X1 of the chain. The selected value results in the max. width Bi. Selection from the table of the appropriate series.

Formula: IRmin. = X1 + 25mm

Example:

Available installation space inner radius 311mm + 25mm = 336mm => X1 350mm = Bi 11 (108mm)

4. Determine bend radius R

In principle, the chain bend radius R is determined by the smallest bend radius of the cable. Selection from the table of the corresponding series.

Example:

1. Ø 22mm (7.5xd) => 22mm x 7.5 = 165mm cable bend radius min.

2. 165 =>R 175mm (next larger selected) results => Part No. TC32.11.175/500

5. Determine the required clearance height [H]

An allowance of 170mm is added to twice the value of the selected chain bend radius R.

Example:

R 175mm x 2 + 170mm = H 520mm

Recommendations for designing the twisterchain new without additional components

| Series | AR [mm] | FZmax. [kg/m] α0°- 180° | FZmax. [kg/m] α180°- 360° | v at AR permissible [m/s] | a at AR max. [m/s2] |

|---|---|---|---|---|---|

| TC32 | 400 | 4 | 2 | 1 | 2 |

| 500 | 4 | 2 | 1 | 2 | |

| 600 | 4 | 2 | 1 | 2 | |

| TC42 | 400 | 6 | 3.6 | 1 | 2 |

| 500 | 6 | 3.6 | 1 | 2 | |

| 600 | 6 | 3.6 | 1 | 2 | |

| 650 | 5 | 2.7 | 1 | 1.5 | |

| 750 | 4 | 1.8 | 1 | 1 | |

| 850 | 4 | 1.8 | 1 | 1 | |

| TC56 | 650 | 8 | 5 | 1 | 2 |

| 750 | 8 | 5 | 1 | 2 | |

| 850 | 8 | 5 | 1 | 2 |

Consulting

I look forward to answering your questions

igus® (Pty) Ltd. +27 11 312 1848Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr