Change Language :

Plain bearings in heavy-duty applications

In comparison: lubricated metal bearings and self-lubricating igutex® plain bearings

Overview of the test results

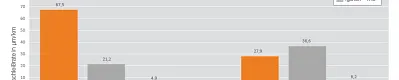

iglidur® and igutex® plain bearings in the wear test with different loads

At 45MPa, both iglidur and igutex return low wear results.

At 75MPa, depending on the shaft used, iglidur Q3E is also a viable alternative to igutex.

At a load of 100MPa, igutex® TX3 exhibits the lowest wear by far.

Further information on the lubrication-free operation of heavy-duty storage points

Our white papers and factsheets provide you with information on a wide range of topics, such as protection against corrosion, dirt and sealing, mounting methods for plain bearings or locating spigots.

Different lubrication methods: Advantages and requirements

Our materials for lubrication-free heavy-duty applications

**

Materials for use in harsh environments**

iglidur® Materials are manufactured by injection moulding or machined from extruded bar stock. Choose from over 8,500 catalogue parts or have your desired design manufactured according to your specifications. In addition to the iglidur® materials for harsh environments, there are also variants for high temperatures, particularly long service lives and other areas of application.

Materials for use under high loads

igutex® fibre composite plain bearings have been specially developed and optimised for use under extreme loads. Due to the flexibility of the winding technology, large diameters can also be manufactured.

References

Consulting

I look forward to answering your questions

igus® (Pty) Ltd. +27 11 312 1848Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr